The future of asset health monitoring is edge-AI: Here’s why

Technology Perspective

Dr. Siddharth Tallur, Co-founder & Director, Nirixense Technologies (August 2025)

Corrosion, construction flaws and overloading can weaken structures, and even lead to catastrophic failures. Continuous monitoring is the best way to preventing such outcomes. Just as fitness trackers monitor our heart rate, sleep, and activity for early signs of illness, structural health monitoring (SHM) does the same for critical infrastructure. It helps asset managers detect early warning signs of deterioration and damage. When hundreds or thousands of assets are spread over long distances, SHM must be scalable and efficient for managing huge volumes of data.

Long-term SHM systems sound promising, yet industries still rely heavily on periodic inspections and non-destructive testing (NDT). The slow adoption comes from a mix of organizational, business, and technical hurdles, well explained by Cawley et al. [1] For SHM to be effective, you need to know where to install sensors. For this, you should either already know exactly where damage is likely to occur, or the damage will be widespread enough that a few sample points can give a good estimate. Moreover, sending raw sensor data to a central server needs huge bandwidth and storage. This is especially true for remote assets like bridges, pipelines, and wind farms or tall structures like multistorey buildings. The solution lies in using artificial intelligency (AI) for processing data at the edge i.e., inside the device itself, so it can detect damage locally and send only clear, actionable alerts to operators.

Learning in the field:

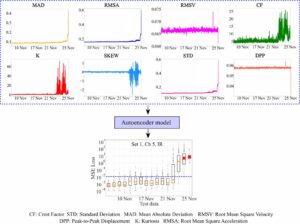

Recent research by our research group at IIT Bombay [2] introduces a novel, explainable unsupervised artificial intelligence (AI) framework for scalable machine fault detection in Industry 4.0. This was tested on 18 machines installed at three factories in India, monitored for several months. This approach is highly relevant for SHM. Using lightweight AI models inside sensor nodes, we can detect faults directly at the edge (i.e., sensor node). These models adapt to changing operating conditions, without needing large labeled datasets or expensive computing.

Instead of training with large volumes of historical data (that are often not available), Asutkar et al. showed how AI models can learn what “healthy” looks like post-deployment. For SHM, this means we can spot early changes in structural behavior, without having to invest in training large AI models.

Smarter monitoring at the edge:

Running AI on edge devices brings three big benefits to SHM:

- Real-time detection at the asset

- Minimal data transfer: only critical alerts

- Scalable monitoring across many sites

At Nirixense, we are adapting these principles to deliver SHM systems optimized for modern IoT infrastructure.

Addressing practical challenges in SHM:

Cutting through noise: One challenge in SHM is telling real damage apart from changes caused by weather or usage or operating conditions. The trend-based classifier approach presented by Asutkar et al. only flags issues that persist, reducing false alarms and making alerts more trustworthy.

Making AI explainable: By using explainable AI, the system shows why an alert was raised, unlike black-box predictors. In SHM, this means faster decisions and more targeted inspections.

Scaling for real-world infrastructure: Proven across multiple datasets, this approach is highly scalable, just like SHM needs to be. Our solutions are:

- Data-efficient: work even with limited damage history

- Scalable: fit for large infrastructure networks

- Explainable: insights, not just alarms

- Edge-ready: ideal for remote assets

As infrastructure ages, the need for smarter monitoring grows even more. We’re creating edge-AI systems that detect problems early and explain their causes, helping you stay ahead of risks. From bridges to pipelines, this shift makes infrastructure safer, more reliable, and future-ready.

References

- Cawley, P. A development strategy for structural health monitoring applications. Journal of Nondestructive Evaluation, Diagnostics and Prognostics of Engineering Systems 4, 041012 (2021).

- Asutkar S. and Tallur S. An explainable unsupervised learning framework for scalable machine fault detection in Industry 4.0. Measurement Science and Technology, 34(10) 105123 (2023).

© 2025 Nirixense Technologies Pvt. Ltd. All rights reserved. email: connect@nirixense.com

About the Author: Dr. Siddharth Tallur is Co-founder & Director at Nirixense Technologies, and Associate Professor at Department of Electrical Engineering, IIT Bombay. His experience includes development of high resolution and low-cost sensors, high-speed instrumentation and embedded smart sensing systems. He obtained M.S.-Ph.D. degree from Cornell University (ECE, 2013), and B.Tech. from IIT Bombay (EE, 2008).

Note: This article presents the author’s personal views and insights drawn from publicly shareable aspects of research projects conducted as a faculty member at IIT Bombay. The content is intended solely for thought leadership and knowledge sharing. The views expressed do not necessarily represent those of IIT Bombay.