Rebar mapping and drawing verification in a decade old bridge using ReX 100

Case Study

Om Narayan Singh, Applications Engineer, Nirixense Technologies

Sai Srikar Kolluri, Product Manager, Nirixense Technologies

Divya Koppikar, Product and UI/UX Designer, Nirixense Technologies

(December 2025)

This case study documents a detailed structural assessment of a 10+ year old reinforced concrete bridge in Greater Mumbai through high-resolution non-destructive rebar mapping. The objective was to determine whether the in-situ reinforcement configuration remained consistent with the original design intent and satisfy requirements for serviceability.

Watch the full on-site investigation in our YouTube video:

Overview:

The investigation focused on three critical components of the structure:

- Interior box girder: Partition wall & deck slab bottom surface (torsional and flexural load interfaces)

- Pier: Curved surface (high lateral load demand)

- Pier: Flat surface (primary axial load path)

We tested the ReX 100 rebar scanner on this structure to evaluate its signal stability under field vibration and its ability to detect multiple layers of reinforcement on rough surfaces.

Challenges:

Aging reinforced concrete structures often develop irregular surface and subsurface conditions that make non-destructive testing more difficult. In this structure, several factors were present that could distort or add errors to electromagnetic scans:

- Unknown reinforcement condition: After years of operation, the reinforcement may have shifted, corroded, lost cross-section, or become misaligned, all of which could affect structural performance.

- Dynamic vibration: Traffic loads caused continuous vibration in the piers, which could affect sensor contact and signal stability.

- Irregular geometry: The curved pier surface made it harder to keep the scanner aligned and maintain good sensor coupling.

- Surface degradation: Dust, worn concrete, and uneven textures could weaken electromagnetic signals and reduce detection accuracy.

- Limited access and visibility: The interior of the box girder had low lighting and tight spaces, complicating both inspection and scanning.

Solution:

The investigation combined a visual survey, grid-based electromagnetic scanning, and digital post-processing of the scan results. The ReX 100 was used in multiple passes to help reduce signal noise caused by vibration and complex geometry. The scanning protocol included:

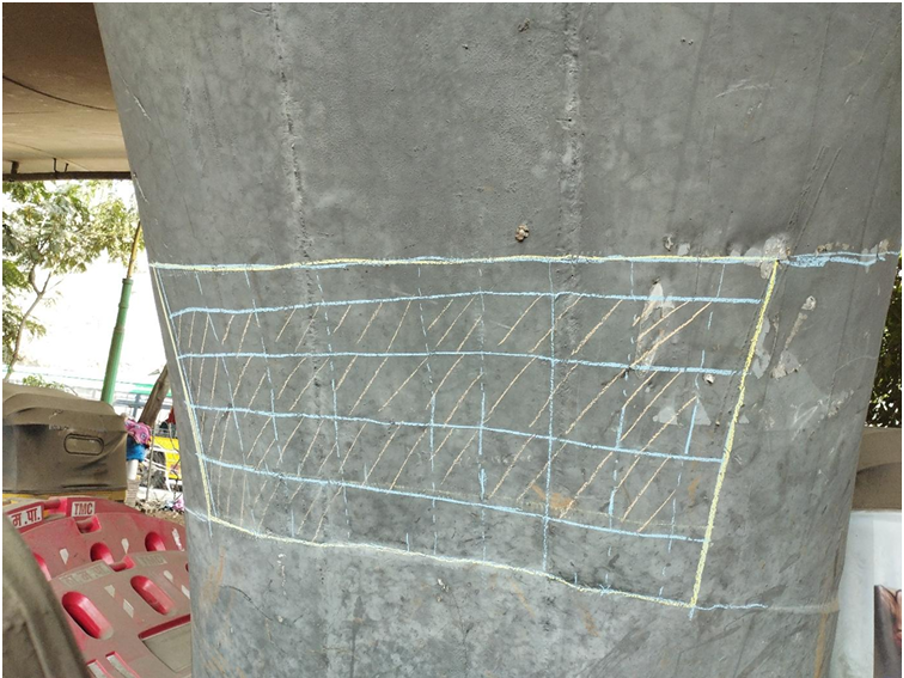

- Grid layout and surface marking: Chalk grids (both orthogonal and aligned with the pier’s curvature) were applied to guide the scanner along consistent paths.

- Multi-pass scanning: Horizontal, vertical, and diagonal passes were completed as needed to provide redundancy and improve detection of mesh or multi-layer reinforcement.

- On-the-spot verification: Real-time on-screen feedback was used to confirm bar locations and continuity before finalizing each scan area.

- Data export and analysis: All scan data were transferred to the ReX 100 mobile app (ReX Connect) for depth analysis, bar spacing checks, and comparison with the original structural drawings.

This workflow allowed precise correlation between field-detected reinforcement and original design drawings.

Technical assessment of key structural components:

1. Pier – Curved surface

The curved segment of the pier is mechanically significant because curvature induces non-uniform bending stresses and necessitates closely spaced reinforcement to maintain ductility and confinement. From a scanning perspective, curvature also disrupts the electromagnetic field’s perpendicular alignment with embedded steel, causing potential attenuation of signal if not positioned correctly.

Despite these inherent challenges, the ReX 100 maintained stable coupling with the surface due to its optimized sensing geometry. By aligning the scanning grid tangentially to local curvature radii, the device generated consistent amplitude peaks corresponding to rebar locations.

Figure 1: Pier – curved profile

Findings:

- A dense orthogonal reinforcement mesh was identified, aligning with expected detailing for curvature-dominated regions.

- Both primary longitudinal bars and secondary ties exhibited uniform spacing within design tolerances.

- No anomalies in bar continuity, spacing deviation, or depth variability were detected, indicating that the reinforcement cage had remained structurally stable despite long-term dynamic excitation. Bar diameter values were within ±1 rebar specification.

This result is especially noteworthy given that curved surfaces typically produce more false negatives due to inconsistent sensor alignment. The ability of the ReX 100 to resolve bar signatures under curvature reflects its high electromagnetic stability.

2. Pier – Flat surface

The flat face of the pier primarily carries axial loads, transferring compression from the superstructure down to the foundation. The reinforcement along this face plays a key role in maintaining column stability, resisting buckling, and controlling cracking.

Because the surface is planar, the scanning environment was more controlled. Using a carefully marked orthogonal grid, the ReX 100 was able to map the reinforcement layout with high accuracy.

Figure 2: Inspection of flat surface of pier.

Findings:

- Vertical reinforcement bars were detected as continuous, uninterrupted signatures, confirming adequate load path continuity.

- Lateral ties were located at regular intervals, matching confinement detailing required by design.

- Depth readings were consistent with original cover requirements, indicating no significant loss of section or corrosion-induced delamination.

The flat pier surface showed well-preserved reinforcement continuity, indicating that environmental exposure has not yet affected the pier’s axial capacity or its confinement performance.

3. Inside box girder

The interior of the box girder in a bridge has limited access, low lighting, and heavy dust buildup—conditions that usually reduce the reliability of non-destructive testing. The structural elements inside the girder also play an important role in shear transfer, torsional stiffness, and slab flexure.

Partition wall:

The partition wall acts as a web element, resisting both shear and torsional stresses. With the aid of supplemental lighting, long-axis scanning showed continuous vertical reinforcement with spacing that closely matched the original design drawings. No deviations in bar alignment or cover thickness were detected, indicating minimal deterioration in the wall’s shear-carrying capacity.

Figure 3: Scanning zone mapped on partition wall

Deck slab:

The underside of the deck slab experiences repeated flexural stresses from traffic loading. Detecting multiple layers of reinforcement is crucial, as the slab’s performance relies on proper bar arrangement and spacing.

Figure 4: Inspection of deck slab using ReX 100

Findings:

- ReX 100 successfully identified distinct reinforcement layers, indicating proper mesh layout.

- Depth differentials between layers matched the slab’s structural detailing.

- No missing or corroded bar signals were observed, reinforcing confidence in the slab’s long-term flexural reliability.

The ability to differentiate multiple layers in a dusty, low-visibility, uneven environment highlights the resolution capabilities and robustness of the ReX 100 rebar scanner.

Results:

Across all tested areas, the reinforcement detected by the ReX 100 closely matched the original structural drawings. No signs of bar loss, misalignment, displacement, or discontinuity were observed. The device demonstrated:

- Stable electromagnetic performance on curved and vibrating surfaces.

- Accurate mapping of multi-layer reinforcement.

- Reliable depth measurements consistent with the specified cover.

- Effective operation in low-light, confined spaces.

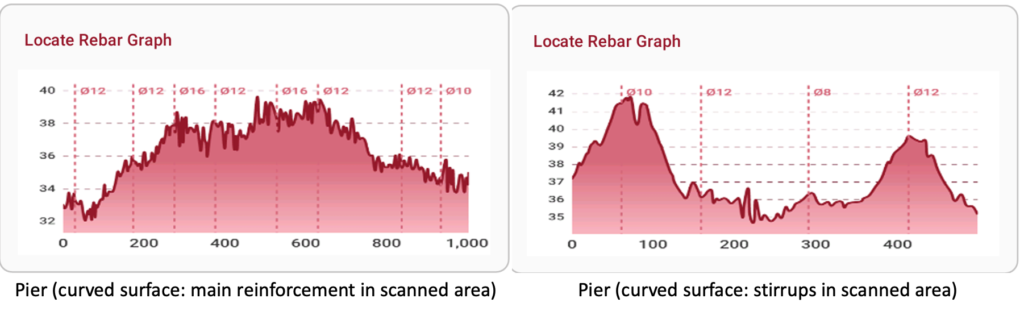

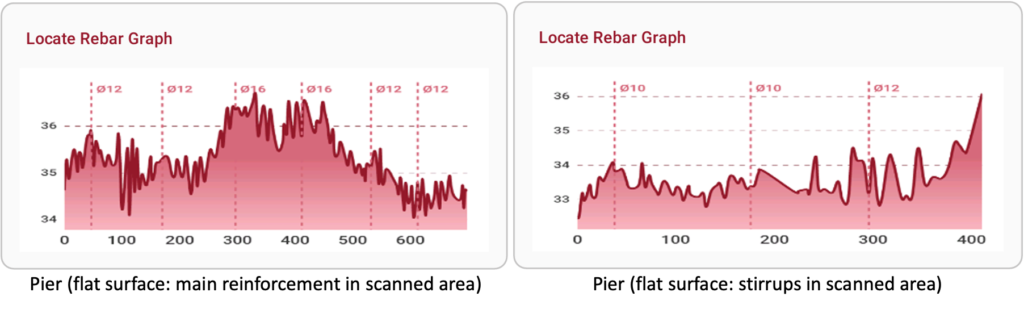

Digital data export from the mobile app in form of PDF report enabled precise and simplified evaluation of bar spacing, depth distribution, and mesh patterns, supporting high-confidence structural verification. Rebar detail graphs of pier from the PDF reports are shown below for reference.

Figure 5: Results for curved surface of pier. Main reinforcement: mean cover = 57.12mm, median diameter = 12mm; Stirrups: mean cover = 39.5mm , modal diameter = 12mm

Figure 6: Results for flat surface of pier. Main reinforcement: mean cover = 72.83mm, median diameter = 12mm; Stirrups: mean cover = 74.33mm , modal diameter = 10mm

Conclusion:

This study demonstrates that the ReX 100 is a reliable tool for verifying reinforcement in aging concrete structures. Its consistent performance on curved surfaces, under vibration, and within girder cavities highlights its diagnostic-level robustness. By enabling precise comparisons between as-built conditions and design drawings, it supports structural assessment, rehabilitation planning, and long-term monitoring.

Watch the complete inspection and rebar mapping process in action on our YouTube channel.