Precision testing of the ReX 100 in challenging shallow cover environments

Case Study

Om Narayan Singh, Applications Engineer, Nirixense Technologies

Dr. Nisheeta Desai, Data Scientist, Nirixense Technologies

Divya Koppikar, Product and UI/UX Designer, Nirixense Technologies

(December 2025)

Introduction:

Accurate detection of reinforcement under shallow concrete cover is critical for structural assessment, retrofitting, and safety planning. This technical report details rigorous laboratory trials of the ReX 100 Rebar Scanner, focusing on its accuracy in estimating rebar position, concrete cover depth, and diameter under shallow cover conditions, for e.g., in slab and beam structures. The evaluation simulates high-interference scenarios, including air cover, rebars with and without stirrups, and both longitudinal and transverse scans to validate the system’s detection fidelity in demanding environments.

Testing conditions overview:

Figure 1: Controlled test setup showcasing the ReX 100’s performance across three scenarios, including baseline no-rebar condition, deep single-layer bars, and complex multi-layer arrangements with stirrups.

| Condition | Scenario | Key focus |

| I | Air cover (no rebar), 58mm | Baseline sensor stability and noise rejection at shallow depth |

| II | 16mm diameter main rebar, 42mm cover, no stirrups | Estimation accuracy under shallow, unobstructed cover |

| III | 16mm diameter main rebars and 8mm diameter stirrups, covers 42mm (main)/34mm (stirrup) | Performance in interference-prone, congested zones (multiple scan directions) |

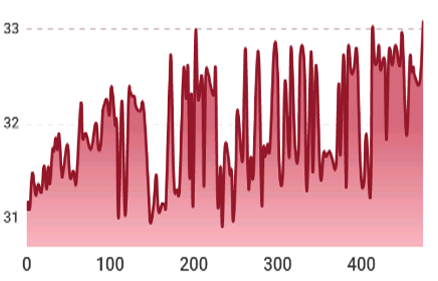

Condition I: Air cover (No reinforcement)

The ReX 100 demonstrated zero false positive rebar detection when scanned over 58 mm of air cover on the table with no reinforcement present. This confirms the scanner’s robust baseline stability, critical for minimizing mistaken readings and unnecessary interventions during site operations.

Figure 2: Result for Condition I: Air cover

Interpretation

- High noise immunity ensures safe operation even at minimal cover thickness.

- No interference from magnetic or electromagnetic artefacts on rebar detection.

Condition II: 16mm diameter rebars, 42 mm shallow cover, no stirrups

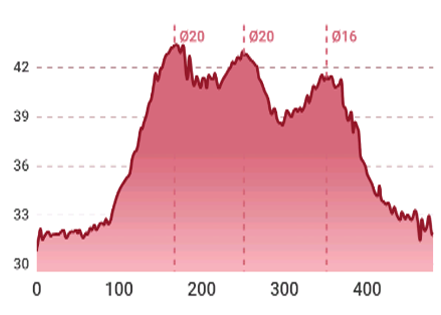

Figure 3: Result for Condition II: rebar diameter 16mm with 42mm cover and no stirrups, scanned in longitudinal direction

Testing 16mm diameter rebars under 42mm concrete cover without stirrups showed:

- Cover depth estimation: Reasonably accurate with ±10 mm.

- Diameter estimation: Slightly higher diameter readings (16mm bars detected as 20mm), within ±1 rebar size specification.

- Scan direction impact: Longitudinal scanning produced consistent, high-quality results demonstrating the scanner’s reliability for precise on-site use.

Condition III: 16 mm diameter main rebars (with 42mm cover) and 8mm diameter stirrups (with 34mm cover)

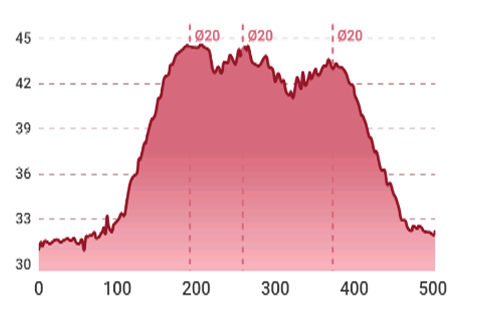

Figure 4: Result for Condition III: rebar diameter 16mm with 42mm cover and 8mm diameter stirrups with 34mm cover, scanned in longitudinal direction

The scanner effectively detected main rebars with no interference from stirrups:

- Longitudinal scans: Maintained location accuracy and improved cover depth estimation (±10 mm), highlighting the scanner’s ability to handle cluttered reinforcement. Diameter estimates remained stable and consistent within ±1 rebar size specification.

- Transverse scans: While more challenging due to smaller diameter, the scanner provides valuable data with clear location detection of stirrup diameters, demonstrating versatility across scan orientations.

Key highlights observed from testing:

- Exceptional detection sensitivity: Reliable detection at shallow covers where conventional scanners may struggle, enabling confident, non-destructive inspections.

- High noise immunity: Eliminates false positives, ensuring scanning efficiency with no false positives.

- Consistent multi-parameter measurement: Simultaneously captures location, cover, and diameter independently, accelerating field workflows.

- Robust performance amidst interference: Effectively distinguishes main rebars in presence of stirrups, supporting scan accuracy in complex reinforcement zones.

- User-centric operation: Ergonomic design and intuitive scanning modes facilitate easy, controlled scanning to maximize precision.

Overall summary and recommendation:

The ReX 100’s advanced edge-AI powered technology and innovative sensor design deliver superior accuracy and operational reliability at challenging shallow depths, making it suitable for core-cutting operation in columns and slabs. Operators are advised to prioritize longitudinal scans and slow, steady scanning motions to leverage the scanner’s full performance. Multiple-scans averaging further enhances confidence in congested rebar configurations.

This rigorous testing reinforces the ReX 100 as a premier tool for structural inspection and core cutting preparation, empowering engineers to conduct safer, faster, and more accurate rebar inspections on-site. It is an indispensable asset for modern construction quality assurance and retrofit projects.