FPGAs vs. Microcontrollers: Choosing the right platform for building smart NDT & SHM systems

Technology Perspective

Dr. Siddharth Tallur, Co-founder & Director, Nirixense Technologies (August 2025)

In the world of non-destructive testing (NDT) and structural health monitoring (SHM), one size never fits all. Sensors and sensor networks are getting more advanced, data volumes are rising, and real-time analysis is now essential. These demands apply across industries such as aerospace, energy, civil infrastructure, and manufacturing. At the core of these systems lies the processing hardware. Two of the most widely used platforms are field-programmable gate arrays (FPGAs) and microcontrollers (MCUs).

Microcontrollers power most of the electronics around us, from home appliances and wearables to industrial automation and IoT devices. Their appeal lies in their versatility: a single low-cost chip combines a processor, memory, and interfaces. Developers can program them in familiar languages such as C/C++ or MicroPython to perform countless tasks. This flexibility makes microcontrollers the default choice in many NDT and SHM instruments as well. In NDT and SHM, microcontrollers are often used to connect with sensors, record and process moderate amounts of data, and handle wireless communication. They also run on very little power and therefore are suitable for longer battery life. For distributed sensor nodes deployed on bridges, wind turbines, or aircraft structures, microcontrollers are the natural fit.

As NDT and SHM systems evolve, the demand for higher data rate, more channels, and real-time analysis often extends beyond what microcontrollers can handle. This is where field-programmable gate arrays (FPGAs) come in. Unlike microcontrollers, which run instructions one after another in a sequential manner, FPGAs allow engineers to create custom parallel hardware inside a chip. This enables processing of multiple high-speed signals simultaneously with no timing mismatch. For applications such as ultrasonic imaging, acoustic emission monitoring, or multi-channel high-speed vibration analysis, FPGAs offer a level of speed, precision, and scalability of computational complexity that microcontrollers simply cannot match.

Why this choice matters:

Smart NDT and SHM systems no longer require just dataloggers. They demand full-fledged edge computing platforms. The choice of processing hardware determines:

- How fast signals can be acquired and processed

- Whether real-time decisions are possible

- How scalable a system is across large structures

- Power consumption and form factor of sensor nodes

- Ultimately, the cost-effectiveness and reliability of the monitoring solution

Comparison at a glance:

| Aspect | FPGAs | Microcontrollers |

|---|---|---|

| Processing style | Parallel, hardware-level processing | Sequential, software-based processing |

| Speed/throughput | Very high, supports MHz–GHz sampling | Limited, usually kHz–low MHz range |

| Real-time performance | Deterministic, precise and predictable timing, no OS latency | Can suffer from latency, unless using real-time (RTOS) carefully |

| Multi-sensor scalability | Excellent, can handle many parallel channels | Limited, speed-channel tradeoff |

| Signal processing | Hardware-accelerated (FFT, filtering, correlation, damage indices etc.) with low latency | Software-based, slower for heavy DSP tasks |

| Flexibility/reconfigurability | Reconfigurable hardware, supports evolving algorithms and faster R&D turn-around | Firmware updates only, less hardware flexibility |

| Development complexity | Difficult (HDL, HLS, toolchains, debugging is harder) | Easier (C/C++ or python programming, easy toolchains, faster prototyping) |

| Power consumption | Higher (not ideal for wireless, battery-powered SHM nodes) | Very low, suitable for portable NDT/IoT SHM |

| Cost | Expensive (chip + dev tools + engineering time) | Low cost, ideal for distributed sensor networks |

| Form factor | Larger boards, more components | Compact, can be embedded in small sensor nodes |

| Possible use cases | High-speed NDT (ultrasonic imaging, acoustic emission, real-time, multi-channel, high-speed, vibration analysis), multi-channel SHM | Low-power SHM (strain gauges, temperature/vibration logging, wireless IoT nodes), portable, battery-powered NDT instruments |

In short, microcontrollers bring versatility, low power and low cost to embedded systems, whereas FPGAs bring performance, precision, and real-time capability. For complex signal processing and real-time analysis, FPGAs are generally better than microcontrollers. Some examples from our research at IIT Bombay are provided as additional reading below. But with careful design, using real-time operating systems (RTOS) and efficient algorithms, microcontrollers can still handle demanding tasks, as shown in our ReX 100 rebar scanner.

As NDT and SHM systems continue to evolve, the most effective solutions won’t come from a company focused on a single technology, but on the intelligent selection of suitable microcontrollers or FPGAs depending on the applications. By harnessing the strengths of each, Nirixense is building the next generation of smart sensors; faster, more efficient, and more insightful than ever before.

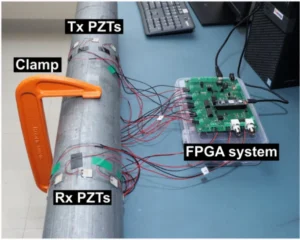

FPGA based smart sensor systems for structural inspection from our R&D at IIT Bombay:

- Sheetal Patil, Sauvik Banerjee and Siddharth Tallur, “Smart structural health monitoring (SHM) system for on-board localization of defects in pipes using torsional ultrasonic guided waves,” Scientific Reports 14, 24455 (2024).

- Pankhi Kashyap, Kajal Shivgan, Sheetal Patil, Ramana Raja B., Sagar Mahajan, Sauvik Banerjee and Siddharth Tallur, “Unsupervised deep learning framework for temperature-compensated damage assessment using ultrasonic guided waves on edge device,” Scientific Reports 14, 3751 (2024).

- Ramana Raja B., Sheetal Patil, Pankhi Kashyap, Siddharth Tallur and Sauvik Banerjee, “The effect of temperature on guided wave signal characteristics in presence of disbond and delamination for health monitoring of a honeycomb composite sandwich structure with built-in PZT network,” Smart Materials and Structures, vol. 32, no. 9, 095003 (2023).

- Shruti Sawant, Sheetal Patil, Jeslin Thalapil, Sauvik Banerjee and Siddharth Tallur, “Temperature variation compensated damage classification and localisation in ultrasonic guided wave SHM using self-learnt features and Gaussian mixture models,” Smart Materials and Structures, vol. 31, no. 5, 055008 (2022).

- Vaibhav Malviya, Indrani Mukherjee and Siddharth Tallur, “Edge-compatible convolutional autoencoder implemented on FPGA for anomaly detection in vibration condition-based monitoring,” IEEE Sensors Letters, vol. 6, no. 4, Art. no. 7001104 (2022)

© 2025 Nirixense Technologies Pvt. Ltd. All rights reserved. email: connect@nirixense.com

About the Author: Dr. Siddharth Tallur is Co-founder & Director at Nirixense Technologies, and Associate Professor at Department of Electrical Engineering, IIT Bombay. His experience includes development of high resolution and low-cost sensors, high-speed instrumentation and embedded smart sensing systems. He obtained MS-Ph.D. degree from Cornell University (ECE, 2013), and B.Tech. from IIT Bombay (EE, 2008).

Note: This article presents the author’s personal views and insights drawn from publicly shareable aspects of research projects conducted as a faculty member at IIT Bombay. The content is intended solely for thought leadership and knowledge sharing. The views expressed do not necessarily represent those of IIT Bombay.