Next generation bridge monitoring with advanced sensing and digital twin technology

Case Study

Dr. Sauvik Banerjee, Co-founder & Director, Nirixense Technologies (August 2025)

With aging bridges carrying heavier loads and facing harsh environments, traditional inspection methods often fail to give timely and accurate results. This article explains how advanced strain sensing, combined with digital twin models, can transform bridge monitoring. By recording real-time data and simulating future behavior, this approach helps detect damage early, reveal stress patterns, and guide predictive maintenance. The result is better safety and longer bridge life.

The problem: Cracks in a prestressed concrete railway bridge

A prestressed concrete railway bridge, built in the 1990s and once seen as an engineering milestone, began to develop cracks in its box girders within only a few years. These cracks raised serious concerns about the bridge’s durability under heavy trains and tough weather conditions. Conventional inspections alone could not detect or predict these risks. A smarter, data-driven monitoring method was needed.

Harnessing strain sensing technology for real-time insights

Our team from IIT Bombay deployed a comprehensive structural health monitoring system using multiple sensors, with special focus on measuring strain:

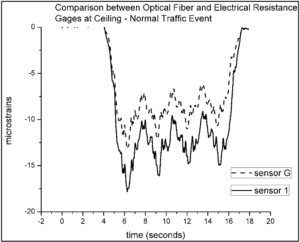

- Electrical and optical strain gauges were fixed on key girder sections to measure strain from train loads.

- Fiber optic crack sensors tracked how existing cracks behaved under dynamic loading.

The sensor network recorded high-quality, real-time strain data for 48 hours, capturing the bridge’s true behavior under normal use.

From data to digital twin: Bridging physical and virtual worlds

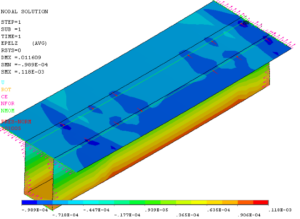

The detailed strain data was used to calibrate a full-scale finite element model, creating a digital twin of the bridge. Unlike traditional models, this digital twin was updated in real time with field data. This allowed:

- Clear visualization of stress distribution and high-stress zones near cracks

- Quantitative analysis to explain the causes of damage

- Predictive simulations of how the bridge may behave under future loads

This method turned raw strain data into practical engineering insights.

Key takeaways for engineers and asset owners

- Multimodal strain sensing ensures reliability: Cross-checking between electrical and optical strain gauges reduces errors in complex bridge conditions.

- Digital twins enable proactive management: Well-calibrated models evolve with the structure, predict weak points, and guide better maintenance decisions.

- Data-driven predictive maintenance extends lifespan: Continuous monitoring shifts bridge care from reactive repairs to planned interventions, improving safety and reducing downtime.

At IIT Bombay and Nirixense Technologies, we combine advanced sensors with digital twin technology for structural inspections. This approach helps engineers and asset owners detect problems early, understand stress and deformation, and predict possible failures.

© 2025 Nirixense Technologies Pvt. Ltd. All rights reserved. email: connect@nirixense.com

About the Author: Dr. Sauvik Banerjee is Co-founder & Director at Nirixense Technologies, and Professor at Department of Civil Engineering, IIT Bombay. His experience includes structural health monitoring, using wave propagation and vibration-based approaches, quantitative nondestructive evaluation of structures, nondestructive testing, modelling of advanced composite structures, structural retrofitting and impact response of structures. He obtained Ph.D. degree from UCLA (Mechanical Engineering, 2003), M.Tech. from IIT Bombay (Civil Engineering, 2001).

Note: This article presents the author’s personal views and insights drawn from publicly shareable aspects of research and consultancy projects conducted as a faculty member at IIT Bombay. The content is intended solely for thought leadership and knowledge sharing. The views expressed do not necessarily represent those of IIT Bombay.