Lessons on longevity: Structural audit of a 20-year-old reinforced concrete building

Case Study

Dr. Sauvik Banerjee, Co-founder & Director, Nirixense Technologies (August 2025)

It is often assumed that a well-designed reinforced cement concrete (RCC) building will easily last 50 to 75 years or more. However, reality can be far more complex. Our team at IIT Bombay recently led a structural audit of a 20-year-old ground plus two-storey RCC building. The results were concerning. Despite being relatively new, the structure showed heavy damage. The audit raised questions about durability, construction quality, and the culture of building maintenance.

The findings not only questioned the long-term durability of the structure but also spotlighted broader challenges in construction quality, environmental exposure, and maintenance culture. This case is a reminder that without proper care and planning, even a modest building can lose decades of its expected life.

The building in context:

The building was a G+2 structure located close to the sea, with long, extended corridors functioning as communal passageways. From a usage standpoint, the building was unexceptional. Yet, in just two decades, it displayed symptoms more typical of structures twice its age. The core issues identified included:

- Extensive water seepage from the roof and walls

- Severe corrosion of reinforcement bars

- Lack of routine structural and cosmetic maintenance

These problems accelerated in the harsh coastal climate, which was not fully considered at the design stage. The signs of structural damage were visible and pervasive:

- Vertical cracks in many peripheral columns

- Longitudinal beam cracks

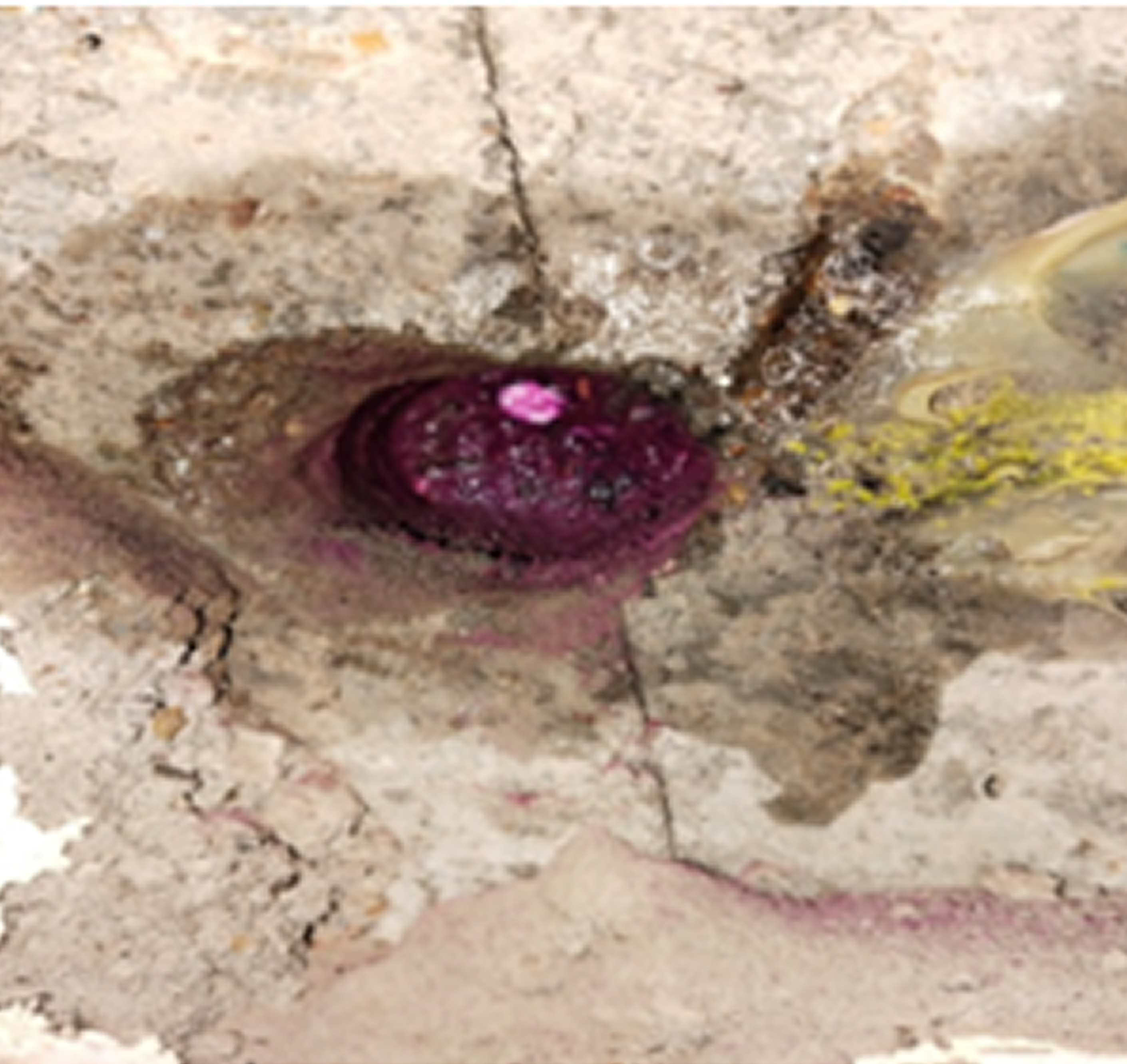

- Spalling of concrete in large segments of slabs

- Warped tiles, uneven floors, and visible slab deflections

- Extensive seepage and leaking due to completely degraded waterproofing system

The distress was not superficial. It extended deep into the structural core of the building.

Diagnosis through NDT:

To check the true condition of the building, a large number of non-destructive tests (NDT) were conducted. These included: rebound hammer, ultrasonic pulse velocity (UPV) test, carbonation test, half-cell potential measurement, core sampling and chemical analysis, and rebar scanner/cover meter testing. Beta test prototype of ReX 100 (CS 100) was used for cover meter testing. The results painted a grim picture:

- Concrete grading ranged from doubtful to poor

- Significant carbonation depth, indicating carbonation-induced corrosion

- High chloride content, causing faster rebar corrosion

- Lack of cover depth, compromising structural durability

- Reduced load-bearing capacity due to widespread corrosion

The residual quality of concrete and steel reinforcement was unsatisfactory.

The root cause – a cascade of neglect:

The building was never given a fair chance to last. Its decline was due to a mix of weak construction, harsh environment, and poor upkeep:

- Repeated wetting-drying cycles in high-humidity environment led to microcracking and chloride ingress

- Chloride ions and carbonation compromised the passive film on steel, causing accelerated corrosion

- With no periodic maintenance, these issues progressed unchecked over years

Dilemma: Repair or rebuild?

While technically feasible, but the scale of specialized retrofitting and repair needed was enormous and economically impractical. Proposals for electrochemical rebar protection, passive cathodic protection system, high-performance concrete overlays & FRP based retrofitting, systemic waterproofing upgrades etc. were evaluated but deemed too costly relative to the building’s utility, age, and current state. After comprehensive analysis and deliberation, the prudent course of action was determined to be to demolish and rebuild.

Lessons for the industry:

This case brings forth critical takeaways for structural engineers, policymakers, builders, and owners alike:

- Design for durability – Factor in local climate, waterproofing, and future maintenance.

- Inspect regularly – Fix leaks, cracks, and corrosion early. Small repairs save money and lives.

- Use NDT regularly – Routine audits with modern tools help detect hidden problems before they escalate.

- Adapt to the environment – Coastal and industrial areas need stronger protection against carbonation and chloride attack.

If you’re involved in infrastructure lifecycle planning, consider integrating structural health monitoring (SHM) systems alongside NDT-driven structural audits and predictive maintenance protocols. This data-driven approach can extend service life and improve resilience.

© 2025 Nirixense Technologies Pvt. Ltd. All rights reserved. email: connect@nirixense.com

About the Author: Dr. Sauvik Banerjee is Co-founder & Director at Nirixense Technologies, and Professor at Department of Civil Engineering, IIT Bombay. His experience includes structural health monitoring, using wave propagation and vibration-based approaches, quantitative nondestructive evaluation of structures, nondestructive testing, modelling of advanced composite structures, structural retrofitting and impact response of structures. He obtained Ph.D. degree from UCLA (Mechanical Engineering, 2003), M.Tech. from IIT Bombay (Civil Engineering, 2001).

Note: This article presents the author’s personal views and insights drawn from publicly shareable aspects of research and consultancy projects conducted as a faculty member at IIT Bombay. The content is intended solely for thought leadership and knowledge sharing. The views expressed do not necessarily represent those of IIT Bombay.